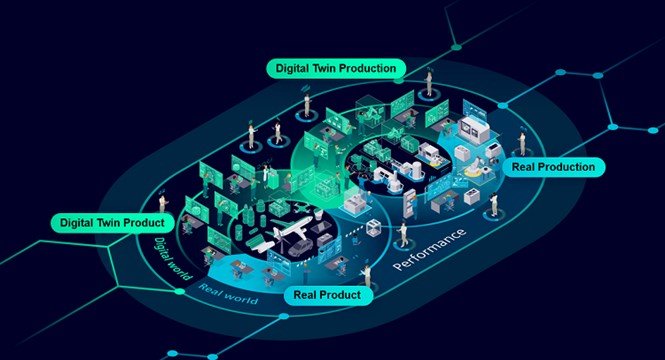

Enhance System Efficiency with Digital Twin Simulation

Next Cellular Tech delivers immersive, real-time digital twin models to simulate, predict, and optimize physical systems

Overview

This technology plays a vital role in sectors such as manufacturing, utilities, logistics, and healthcare—empowering decision-makers to experiment in a risk-free environment, run diagnostics, and fine-tune operations without physical disruption. As a growing B2B force in North America, Next Cellular Tech offers end-to-end Digital Twin Simulation solutions tailored to complex operational landscapes. From architecture to deployment, we help businesses achieve operational resilience, streamline asset lifecycle management, and unlock predictive analytics at scale.

Core Components

Hardware

IoT-enabled smart sensors and actuators integrated with Optical & Imaging Sensors to capture precise conditions for digital twin accuracy.

Edge computing units for localized processing powered by Data Centre Edge delivering scalable and reliable twin simulations.

Industrial-grade RFID tracking systems supported by NFC & HF RFID Readers, Tags & Accessories to enable efficient object mapping in twins.

Real-time data acquisition modules combined with Temperature Data Loggers to feed continuous environmental inputs into simulations.

Communication gateways for integration with existing infrastructure enabled by Wi-Fi HaLow Gateways/Routers for long-range, low-power connectivity in twin ecosystems.

Software

- Real-time physics-based simulation engines

- 3D visualization platforms for digital environments

- Predictive analytics and AI-driven behavior modeling

- Data synchronization and digital mapping tools

- Workflow automation and digital control interfaces

Cloud Services

- Scalable cloud storage for simulation and analytics data

- Digital Twin-as-a-Service (DTaaS) models

- API libraries for integrating with enterprise software (ERP, PLM, SCADA)

- IoT platform connectivity and real-time data streams

- Centralized dashboards for monitoring and simulation control

Key Features and Functionalities

Real-Time Replication

Continuously syncs with physical assets for accurate system monitoring

Predictive Maintenance

Simulates wear, usage, and failure scenarios before issues arise

Process Optimization

Test different operational strategies without real-world risk

Remote Management

Monitor and control assets from centralized or mobile interfaces

Scenario Simulation

Run “what-if” analyses to prepare for changing operational conditions

Benefits of Digital Twin Simulation

Reduced Downtime

Predict and prevent failures with data-driven insights

Operational Transparency

Gain full visibility into asset behavior and system health

Faster Innovation

Simulate new processes or product designs without disruption

Lower Costs

Minimize trial-and-error in physical environments

Sustainable Operations

Optimize energy, resource use, and environmental impact

Integrations & Compatibility

- Integrates with popular ERP, MES, and PLM systems

- Compatible with major cloud providers like AWS, Azure, &

Google Cloud - Interoperates with SCADA, OPC-UA, BACnet, and industrial protocols

- Supports cross-platform data sharing for enterprise-wide visibility

- Built-in AI/ML support for intelligent automation and adaptive learning

Applications

- Smart manufacturing and factory optimization

- Utility grid management and predictive load balancing

- Healthcare equipment performance modeling

- Autonomous vehicle system simulation and validation

- Building management systems (HVAC, lighting, safety)

- Warehouse robotics and material flow simulation

Industries We Serve

Utilities & Energy

Transportation & Automotive

Smart Buildings and Infrastructure

Agriculture & Food Processing

Manufacturing & Industrial Automation

Public Sector & Government

Aerospace and Defense

Healthcare and Medical Devices

Relevant U.S. & Canadian Industry Standards

ISO 23247 – Digital Twin Framework for Manufacturing

ANSI/ISA-95 – Enterprise-Control System Integration

NIST SP 1500 Series –

Cyber-Physical

Systems

CSA S501 – Industrial Control Systems (Canada)

ISED Regulations for Connected Device Data Handling

Case Study

Automotive Assembly Line Optimization in Michigan

An auto manufacturer in Michigan partnered with Next Cellular Tech to implement a digital twin of its assembly line. The simulation identified process bottlenecks and reduced downtime by 40%, while enabling predictive maintenance that decreased unscheduled halts across three facilities.

Smart Building Simulation in Texas

A real estate development firm in Texas utilized digital twin models from Next Celluar Tech to simulate HVAC systems, lighting controls, and occupancy flow. The result was a 25% reduction in energy costs and a data-backed approach to optimizing tenant comfort.

Energy Grid Monitoring in Ontario

In Ontario, a regional energy provider deployed digital twins to simulate substation performance and transformer behavior under varying loads. With nextcellulartech’s guidance, the provider improved reliability and introduced dynamic load balancing based on real-time modeling and forecasting.